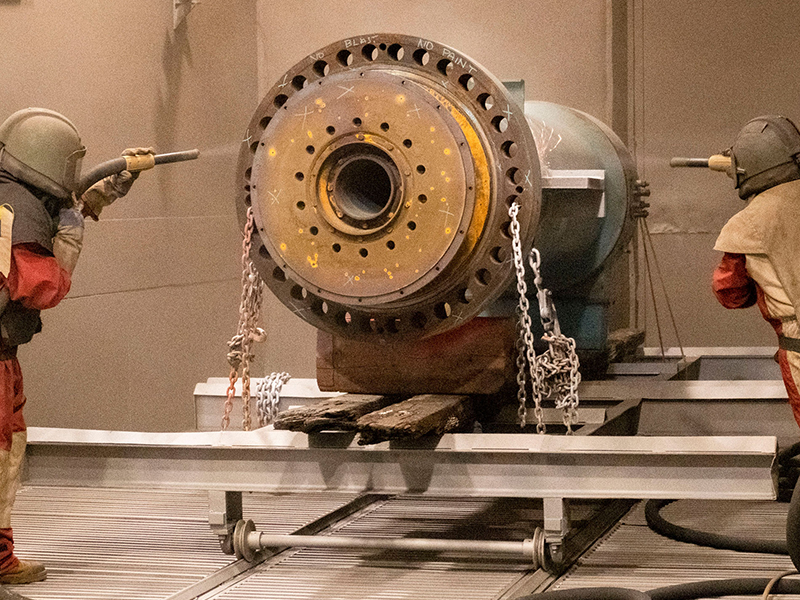

Abrasive Blasting

Abrasive Blasting (Known as : Sandblasting) in Sydney & Newcastle

With any applied coating, the quality of the surface preparation is the most important factor in determining whether the coating will perform for its expected design life.

With paint coatings in particular, almost all failures are due to poor surface preparation. Longer maintenance free performance is being demanded of protective coatings, and environmental and heritage issues increasingly impact upon surface preparation technology. The specification and quality assurance of surface preparation thus require as much attention as the priming and top coating systems. There are no shortcuts to good surface preparation and the costs of premature failure render the savings associated with cheap surface preparation insignificant.

What is abrasive blasting/sandblasting?

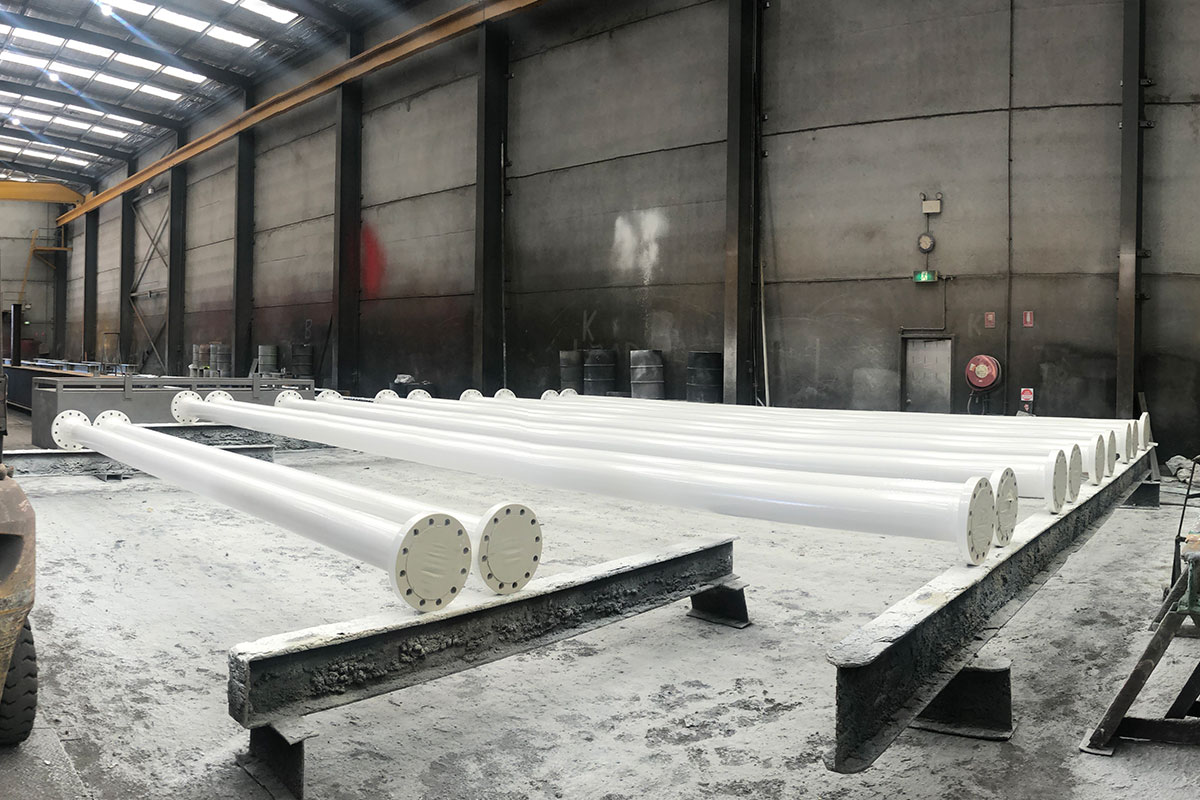

Abrasive blasting (often referred to as sandblasting) is a fast and cost-effective method of surface preparation used for cleaning steel. It creates a roughened surface profile suitable for optimal adhesion for most coating systems including commercial strength paint for protective and aesthetic qualities. Impact cleaning of abrasive particles also removes mill scale, rust, paint, and other tough, brittle contaminants.

The performance of any paint coating is directly dependent upon the correct and thorough preparation of the surface prior to coating.

The most expensive and technologically advanced coating system WILL fail if the surface pretreatment is incorrect or incomplete. CCMP carry out both wet and dry abrasive blast cleaning strictly according to the specified standards as required for each project. A variety of abrasive media can be used to achieve the specified class of blast required for your individual project specifications.

OUR ABRASIVE BLASTING FACILITIES

Our workshop less than 45 Minutes from Sydney & Newcastle metro areas

- We can transport your material to our facility

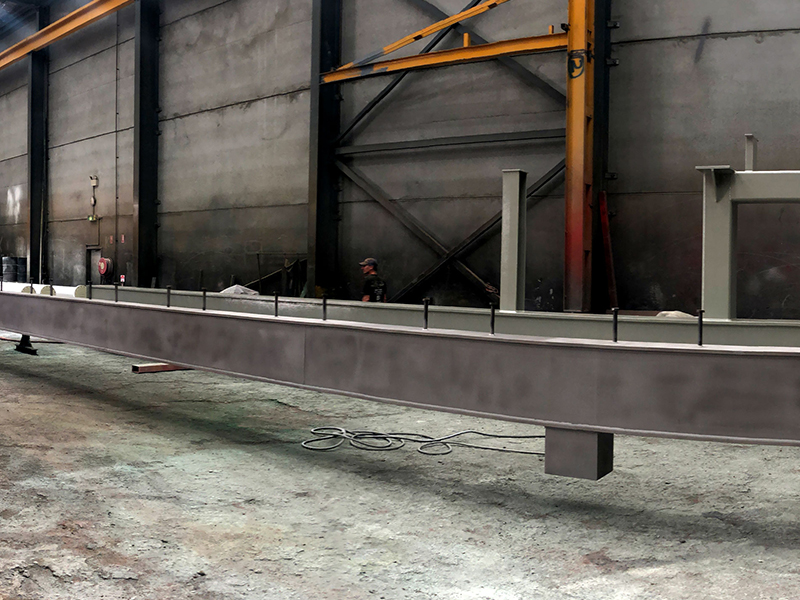

- Workshop 1 Capacity: 2000 sqm Up to 18.5 M x 5 M x 5 M high blasting chamber

- Workshop 2 Capacity: 1000 sqm 12 M x 6 M x 6 M high blasting chamber

- YARD: Fully concreted area (over 4000 M²) for storage of incoming/outgoing goods and to minimise dust.

- Fleet of forklifts up to 10 Tonne capacity service the yard area.

- CCMP have carried out abrasive blasting of structures up to 40 M in length and overhead crane capacity up to 20 Tonnes

- CCMP are also equipped to carry out surface preparation on-site, including vacuum head blasting for hard to access areas.

- Workshop powered by 100 KW Solar System

Got a question? We welcome your enquiries, call now.

Why choose CCMP?

We are a large, well-equipped total corrosion control service provider on the east coast of Australia. We have the facilities and equipment to:

- Collect your steel structure or product in one of our fleet of trucks and prime movers,

- Prepare the surfaces for abrasive blasting, industrial spray painting , protective metal coating and abrasive blasting/sandblasting processes in Sydney, Newcastle and wider NSW in-house and in accordance with your specifications, and

- Service any project (industrial or domestic), no matter how big, small or complex.

Once we have carried out sandblasting in Sydney or wider NSW, the exposed ‘raw’ steel is highly subject to immediate rust, even in transit. The benefit of having the abrasive blasting and protective metal coating completed at the one site is therefore obvious. As general rule of thumb, protective coating must be applied to steel within 4 hours of blasting.