Hot Metal Spray

Hot Metal Spray Coatings in Sydney & Eastern Coast of Australia

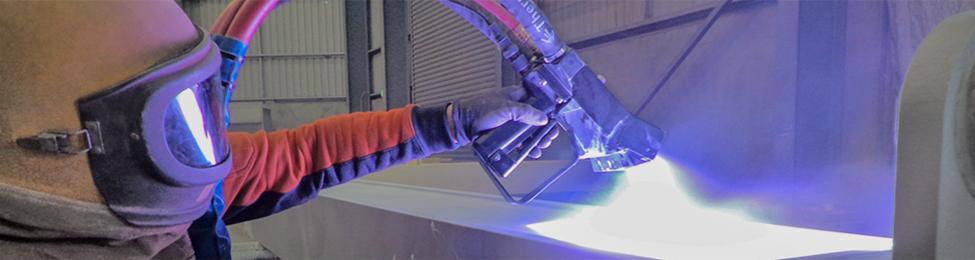

Hot Metal Spray or Thermal Arc Spray or Metallising, provides a superior quality finish with greater performance than painting or hot dipped galvanising.

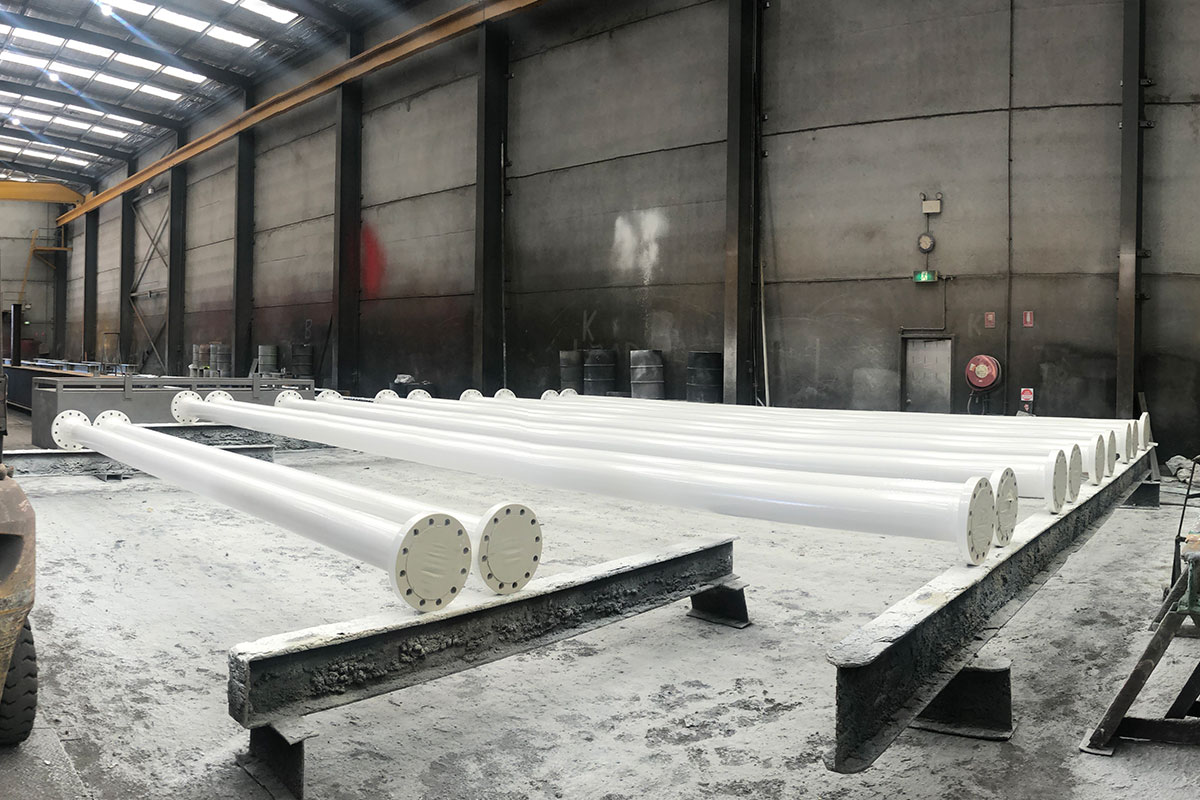

The process of Hot metal spray is where zinc, aluminium or Zinc85/Aluminium15 or other alloys are sprayed onto a substrate, providing a highly protective sacrificial coating or even as a desired architectural finish. Coatings can be applied to not just metals but some plastics, ceramics, concrete surfaces and a range of other substrates.

Coatings can be applied to not just metals but some plastics, ceramics, concrete surfaces and a range of other substrates.

Why choose CCMP for Thermal Arc Spray?

CCMP is one of only a few companies that has the capacity and latest equipment for the application of thermal arc spray of zinc and/or aluminium for cost-effective life cycle protection of clients’ critical structures and assets. We have the ability to:

- Collect your steel structure or product in one of our fleet of trucks and prime movers,

- Prepare the surfaces for abrasive blasting, industrial spray painting , protective metal coating and abrasive blasting/sandblasting processes in Sydney, Newcastle and wider NSW in-house and in accordance with your specifications, and

- Deliver your renewed and protected steel structure or product back to you.

- Service any project (industrial or domestic), no matter how big, small or complex.

Once we have carried out sandblasting in Sydney or wider NSW, the exposed ‘raw’ steel is highly subject to immediate rust, even in transit. The benefit of having the abrasive blasting and protective metal coating completed at the one site is therefore obvious. As general rule of thumb, protective coating must be applied to steel within 4 hours of blasting.